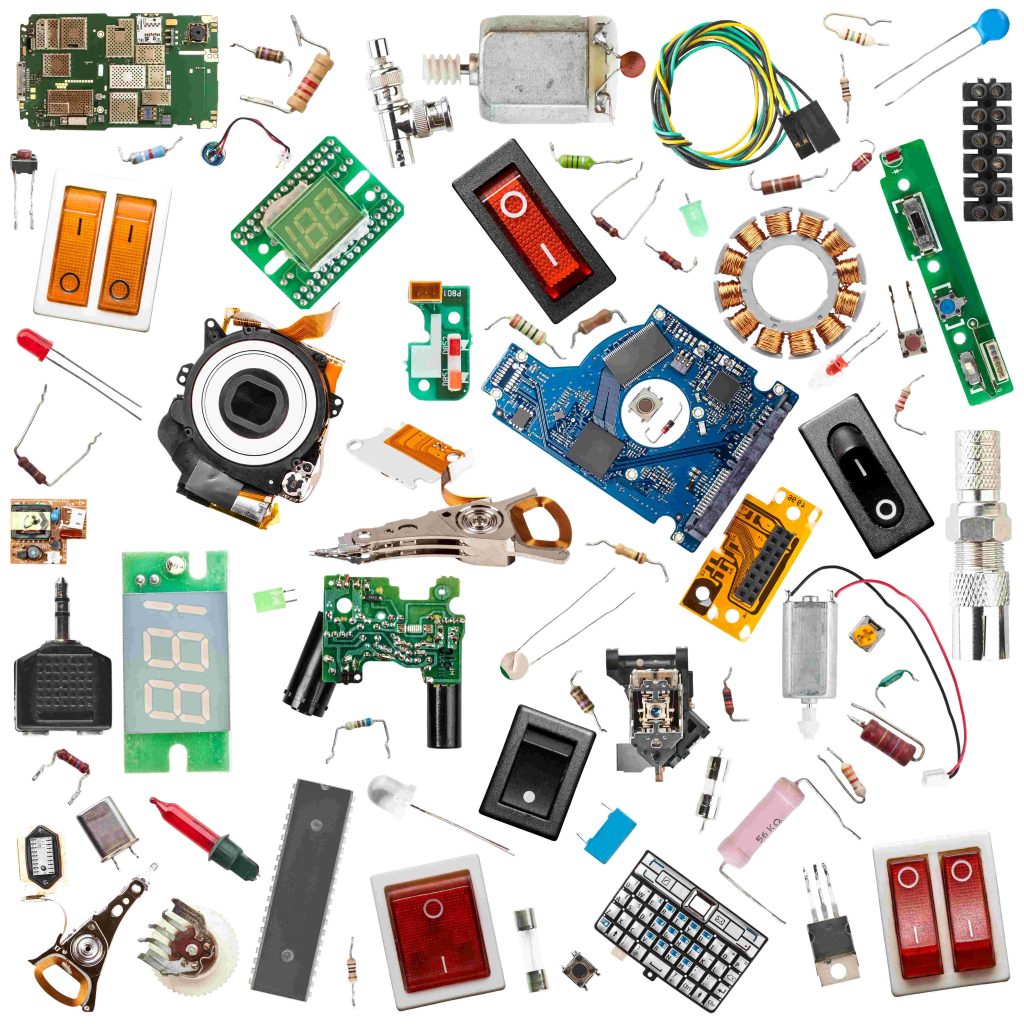

Counterfeiting issues in electronics extend well beyond batteries and affect the entire industry. These fake components not only jeopardize the quality of the goods in which they are utilized, but they also put a strain on the legal component business. The greatest approach to combat an issue like this is to bring it to light and figure out how to stop it from spreading. So, what can you do to spot counterfeit electronic components?

Counterfeit Electronic Components Cause Problems in the Electronics Industry

Attempting to pass off lower-spec parts as higher-spec parts by changing part numbers, repackaging them, or even mixing them in with higher-quality parts is an example of counterfeiting components. Older components are occasionally marketed as new, while faulty parts are marked as working and resold. These counterfeit parts will not have undergone the same rigorous testing and validation procedures as components designed for high-demand or harsh operating conditions. This lack of testing can lead to catastrophic failures of technology that is used in medical, aviation, or military applications.

Some Techniques for Detecting Fake Electronic Components

Counterfeiters start by obtaining the components they require, which may be done in a variety of methods. People are sometimes paid to remove components from stolen devices, while lawfully dumped electronic trash is sometimes repurposed. These components will have their real origins hidden by sanding, burning, or acid washing, and then re-branded as high-quality parts using digital printing processes. Here are several ways to tell if your components are genuine or not:

Visual inspection: It’s crucial to compare your components to a well-known good example. Look for inaccurate or misspelled information, incorrect part numbers or date codes, mislabeled or inappropriate packaging for the part type, and logos and typefaces that don’t match those of the original component maker throughout your examination.

Extensive investigation: When contrasted to your beneficial component, a closer investigation may show more difficult issues:

By sanding the component’s thickness and edges to erase the original codes, the component’s thickness and edges can be changed. Look for crooked edges, as well as size and appearance differences.

Look for blacktopping, which is when a part is resurfaced to disguise its original marks and replace them with new ones. The real component should have a rough surface rather than the blacktopping, and a counterfeit’s fake covers and markings may be removed with solvent.

Make that the pins on the new component match the ones on the old one. Counterfeit components may have pins that are irregularly spaced or exhibit indications of oxidation.

The molding process of a genuine item creates consistent indents in the packaging for pin marks or other uses. A counterfeit part may include irregular indents, as well as marks or blacktopping.

X-ray inspections: This level of examination can reveal whether your component’s dies are of different sizes, if the part is delaminated, or if any of the wire bonds are damaged or missing.

Components can also be electrically checked to ensure that they are in good working order before being used.

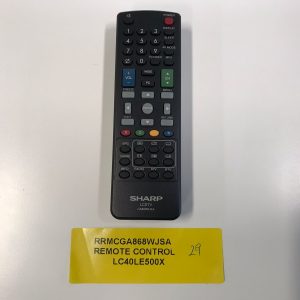

You Can Trust These Component Sourcing Resources

QC Electronics is the best choice for Sharp microwave oven parts because they have a large selection of Sharp microwave oven parts in stock and they are reliable. Their prices are competitive, too.